Roasting: Foundation

#CaffeinatedTraining

#OilSlickCoffee

Presented: November 28th, 2018

Host: 5758 Coffee Lab

Location: Bandung, Indonesia

Press "h" for keyboard shortcuts for this presentation

Three Burner Types

Atmospheric burner (gas burner)

Electric burner (like toaster oven)

Infrared burner (ceramic plates in BBQ grill)

Electrical burners possible on small (batch size 12 and less) roasters. Electrical heating elements are slow but are fine for roasting.

Electricity always drives motors and general control circuits.

Heat Transfer Methods

Convective

Conductive

Radiative

Related:

Endothermic

Exothermic

Two most common: convective and conductive. Convective involves moving air. Conductive requires physical contact and a temperature gradient. Drum rotation important here

Radiated heat example: the light emitted from a red-hot heating element in a toaster

Keywords: Convection Conduction Endothermic Exothermic

Roasting Plant Safety

Three areas of concern:

Fire

Ventilation

Personal safety

- Create an emergency plan ahead of time

- Discuss the plan with everyone

- Create a cleaning + maintenance plan

- Regularly review procedures and plans

Given a long enough timeline, everyone will experience a fire.

Personal safety examples: loading coffee (heavy weight over head, maybe on stool, etc)

Smoke in roasting (ventilation, as smoke does escape the roaster into the room)

Personal hazard areas:

Green coffee storageRoastingPackaging, productionshippingKeywords:

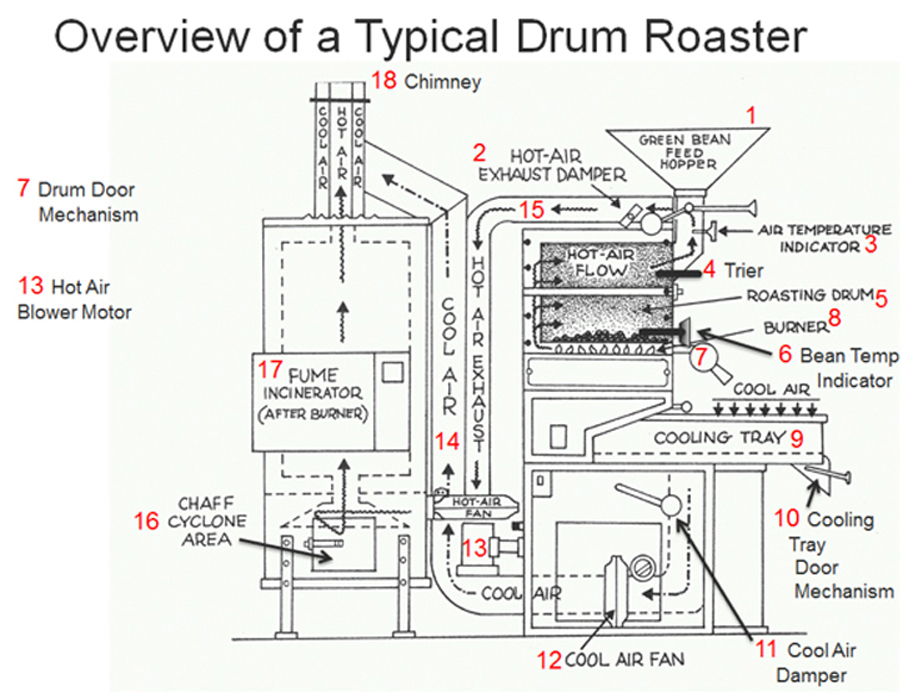

Airflow, chimney

Chaff. Chaff collector

Fire extinguisher (water vs. CO2)

Fire in the chimney

Fire in the drum

Stirring device/agitator/cooling bin (long, draping clothes)

Roaster fires

- Shut off gas (or element if electric)

- Keep drum rotating

- Don’t open roaster doors

- Don’t eject beans

Personal Safety Concerns

Four areas of concern:

- Green coffee storage

- Roasting

- Packaging, production

- Shipping

What are some concerns in these areas?

Fire Classifications

- Class A

Ordinary items (wood, paper, plastic, rags) - Class B

Flammable Liquids - Class C

Electrical equipment

Roaster Cleaning & Maintenance

- Remove chaff often (fuel source for fire)

- Know where chaff collects in your roaster

- At least daily, more for “chaffy” beans

- Keep ducts clear/clean (creosote & chaff)

- Keep moving parts lubricated (food grade grease)

- Follow manufacturer’s manual and recommendations

Physical changes in the bean

- Dries out

- Progressively darkens

- Becomes increasingly brittle

- First Crack

- Size can increase 30 - 100%

- Second crack

- Eventually oil seeps out (especially beyond second crack)

- Sometimes get divots (can be a roast defect)

- Rapid cooling (≤ 4min) to halt chemical reactions (changes)

First Crack and Second Crack

- Every successful roast has a first crack

- First crack is the result of rapid release of pent-up vapor/steam pressure and CO2

- Not all roasts reach second crack (operator’s preference)

- Exothermic flashes as escaping heat affects environment

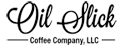

Roast Data

Measurements that can be collected from green and roasted coffee:

- Green: batch weight

- Green: bulk density

- Green: volume

- Green: screen size

- Green: moisture content (acceptable range for Specialty?)

- Roasted: color

- Roasted: weight*

- Roasted: bulk density*

- Roasted: volume*

Cupping data should be associated with roast profile for post-roast analysis.

*Calculate percent changes for these attributes

Label the following on a typical roast profile

Charge

Turning Point

Color change: green to yellow

First crack

Second crack

Roast End

Roast Progression

Lighter roasts highlight (preserve) acidity, enzymatic flavors/aromas

Darker roasts emphasize chocolatey, nutty, bitter flavors/aromas

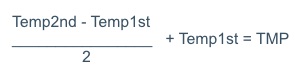

Temperature Midway Point ≈ 75 Agtron

- New concept

- Generates easy color to work/train with

- Not meant to be a standard or a sweet spot regarding end product

Value 4 Value

If you found this content useful, please consider supporting my work. I charge no set fee or price for providing this. You can help keep information like this openly accessible by matching the value you received in the content; value 4 value.

Ko-fi / Bitcoin Wallet: 32SW9kcAsJdZvQKBazhLUZBSD9YS8DDqe8

End of presentation