SCA Roasting Foundation

Study Guide, v1.0

Press "h" for keyboard shortcuts for this presentation

How to use this guide?

Print a copy of the notes

As you progress through the slideshow, fill in the blanks and solve the problems in the notes

Study your notes (including familiarizing yourself with the keywords)

Bring your completed notes to class and add to them. We'll be handing out the same notes in class!

Pass the test like a boss

Know thy roaster!

Three Burner Types

Atmospheric burner (gas burner)

Electric burner (like toaster oven)

Infrared burner (ceramic plates in BBQ grill)

Three Burner Types

Atmospheric burners are fast and responsive

This can be both good and bad; fast = easy to overcompensate

Three Burner Types

Electric burners are good below 12kg capacity

Slow to respond; are like steering a boat (think drift)

Three Burner Types

Infrared burners are energy-efficient

But also slow to respond. Gas heats another material (often ceramic) which in turn heats the environment.

Deidrich uses IR burners

Heat Transfer Methods

Convective

Conductive

Radiative

Convective

- Air as a medium or vehicle

- Most common transfer method in drum and air roasters

- The greater the temp difference between air and bean greater the transfer (potential)

Convective

Conductive

- Physical contact + temperature gradient

- Common cause of roast defects

- Temperature gradient inside bean

- Water content is critical

Convective

Conductive

Radiative

- Electromagnetic radiation (same as the sun)

- Some visible, some not

- Example: light from heat source, heat felt near a heat source

- Metal in roaster acts as a battery, storing energy as heat

- Especially the drum, backplate, and faceplate

Roasting Plant Safety

Three areas of concern:

Fire

Ventilation

Personal safety

- Create an emergency plan ahead of time

- Discuss the plan with everyone

- Create a cleaning + maintenance plan

- Regularly review procedures and plans

Safety Definitions

Fire Safety

Keeping your equipment, staff, products, and customers safe from fires.

Safety Definitions

Fire Safety

Ventilation Safety

Keeping your staff and customers safe from dangerous gasses and airborne particles (such as dust from green coffee or micro-fibers from jute bags).

Safety Definitions

Fire Safety

Ventilation Safety

Personal Safety

Keeping your self and your staff safe and free from harm or injury

Roaster fire hazards

Roaster fires

What to do:

- Stay calm

- Shut off gas (or heating element if electric)

- Shut off exhaust fan and close exhaust damper if possible

- Keep drum rotating

- Use water hose or quenching system if you have it (pulse 10 seconds on, 10 seconds off)

- Don’t eject beans

- Monitor the bean temp

- If you have an afterburner, leave it on

- If stirer arms are on, turn them off

- If cooling fan is on, turn it off

- Extinguish any fire outside drum

- Don't drop the beans until the BT is below 93°C/200°F

- Call the fire department when necessary

Oxygen is a fuel source. By opening either door to the roaster drum, you will inject more oxygen into the drum.

If the beans in the drum are on fire, keep them in the drum where the fire is contained (the drum is fireproof).

List adapted from Marty Curtis's list

Personal Safety Concerns

Four areas of concern:

- Green coffee storage

- Roasting

- Packaging, production

- Shipping

What are some concerns in these areas?

Fire Classifications

- Class A Ordinary items (wood, paper, plastic, rags)

- Class B Flammable Liquids

- Class C Electrical equipment

Roaster Cleaning & Maintenance

- Remove chaff often (fuel source for fire)

- Know where chaff collects in your roaster

- At least daily, more for “chaffy” beans

- Keep ducts clear/clean (creosote & chaff)

- Keep moving parts lubricated (food grade grease)

- Follow manufacturer’s manual and recommendations

Physical changes in the bean

- Dries out

- Progressively darkens

- Becomes increasingly brittle

- First Crack

- Size can increase 30 - 100%

- Second crack

- Eventually oil seeps out (especially beyond second crack)

- Sometimes get divots (can be a roast defect)

- Rapid cooling (≤ 4min) to halt chemical reactions (changes)

First Crack and Second Crack

- Every successful roast has a first crack

- First crack is the result of rapid release of pent-up vapor/steam pressure and CO2

- Not all roasts reach second crack (operator’s preference)

- Exothermic flashes as escaping heat affects environment

Roast Data

Measurements that can be collected from green and roasted coffee:

- Green: batch weight

- Green: bulk density

- Green: volume

- Green: screen size

- Green: moisture content (acceptable range for Specialty?)

- Roasted: color

- Roasted: weight*

- Roasted: bulk density*

- Roasted: volume*

Cupping data should be associated with roast profile for post-roast analysis.

*Calculate percent changes for these attributes

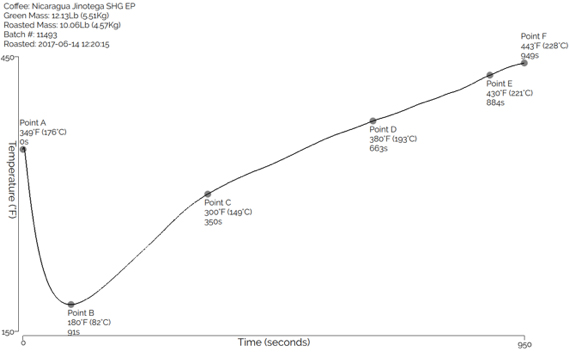

Label the following on a typical roast profile

Charge, Turning Point, Color change: green to yellow, First crack, Second crack, Roast End

Roast Progression

Generally speaking:

Lighter roasts highlight (preserve) acidity, enzymatic flavors/aromas

Darker roasts emphasize chocolatey, nutty, bitter flavors/aromas

Why?

As the roast progresses, organic acids are broken down.

Also, with darker roasts, the Maillard reaction has more time to react. The flavors most associated with the Maillard reaction are chocolatey, nutty, and bitter flavors and aromas.

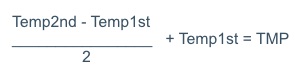

Temperature Midway Point ≈ 75 Agtron

- New concept

- Generates easy color to work/train with

- Not meant to be a standard or a sweet spot regarding end product

End of presentation